When it comes to maintaining the longevity and performance of marine engines, one crucial yet often overlooked component is the zinc anode. Having spent countless hours working on marine engines and battling the challenges of corrosion, I can tell you firsthand just how essential these little metal pieces are. If you’re a boat owner or marine enthusiast, understanding the role of zinc anodes can save you from costly repairs and downtime. So, let’s dive into why these anodes are so important, how to choose the right one, and how to keep them in top shape.

What Are Zinc Anodes and Why Are They Important?

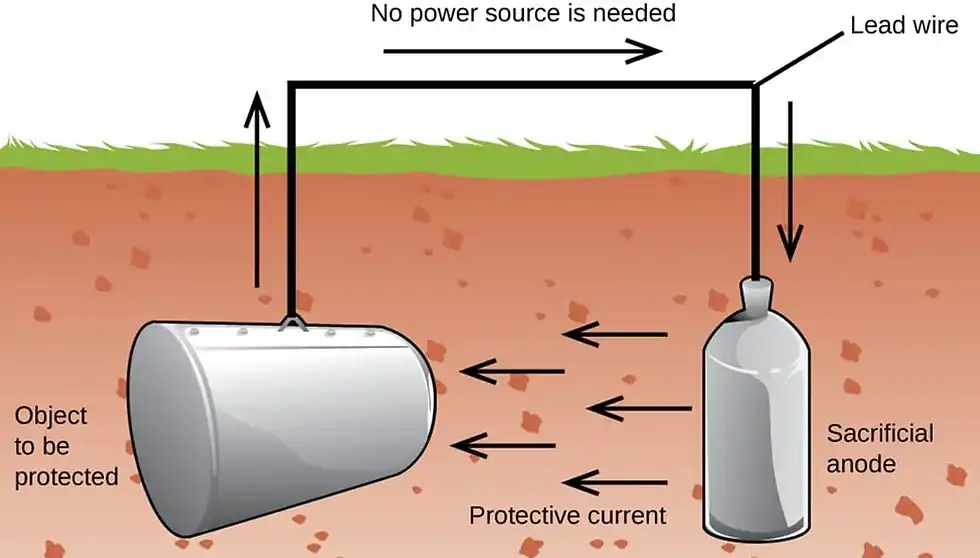

Zinc anodes, also known as sacrificial anodes, play a critical role in protecting metal components from corrosion. Corrosion is a natural process where metals degrade when exposed to moisture and electrolytes, and it’s particularly aggressive in marine environments due to saltwater.

Zinc anodes work by sacrificially corroding themselves instead of the metal components they are designed to protect. In simple terms, zinc is more reactive than other metals commonly used in marine engines, such as aluminum or steel. This means zinc will corrode first, thus sparing the engine parts from degradation. Think of it as a knight in shining armor taking the hits for its king!

How Zinc Anodes Work

Here’s a step-by-step breakdown of how zinc anodes protect your marine engine:

- Electrochemical Reaction: When your boat’s metal parts are submerged in saltwater, an electrochemical reaction occurs. Saltwater acts as a conductor, allowing electricity to flow and causing metal parts to corrode.

- Sacrificial Corrosion: Zinc anodes, being more reactive, corrode more readily than the engine components. They are strategically placed in areas prone to corrosion, such as the propeller, stern drive, and rudder.

- Protection: As the zinc anode corrodes, it creates a protective layer on the metal parts of your engine, thereby preventing them from rusting and deteriorating. It’s like having a personal bodyguard that takes all the blows!

Choosing the Right Zinc Anode

Selecting the correct zinc anode for your marine engine involves several considerations:

- Engine Type and Size: Different engines and boat sizes require different anode sizes and types. Ensure you choose an anode that matches the specifications of your engine and its components. Check your engine’s manual or consult with a marine technician if you’re unsure.

- Material Compatibility: Zinc anodes are designed specifically for saltwater environments. If you’re using your boat in freshwater, you might need a different type of anode, such as an aluminum one, which is more suitable for freshwater.

- Anode Placement: Placement is crucial for effective corrosion protection. Common locations include the propeller shaft, rudder, and transom. Make sure the anodes are placed in areas where they can effectively counteract corrosion.

- Quality and Brand: Not all zinc anodes are created equal. Opt for high-quality anodes from reputable brands. I’ve had great experiences with brands like Martyr, Boats.net, and Anode. These brands offer reliable products that stand up to harsh marine environments.

Tips for Installing Zinc Anodes

Proper installation is key to maximizing the effectiveness of your zinc anodes. Here’s a step-by-step guide to help you out:

- Preparation: Ensure the surface where the anode will be attached is clean and free of rust or paint. Use a wire brush or sandpaper to clean the area.

- Fit and Secure: Attach the anode to the metal part using the mounting hardware provided. Ensure a snug fit to avoid any gaps where moisture could cause corrosion.

- Check Electrical Connectivity: For optimal protection, the anode must have a good electrical connection with the metal parts. If the connection is poor, corrosion protection will be compromised.

- Regular Inspection: After installation, regularly inspect the anodes for wear and tear. Replace them when they are about 50% depleted to ensure continuous protection.

DIY Maintenance Tips

Keeping your zinc anodes in good condition involves regular maintenance. Here are some DIY tips to help you:

- Regular Checks: Inspect your anodes every few months or after significant use. Look for signs of excessive wear or corrosion.

- Clean the Anodes: Remove any build-up of marine growth or debris on the anodes. Clean them gently with a wire brush or a soft cloth.

- Monitor Engine Parts: Pay attention to the condition of your engine parts. If you notice any signs of rust or corrosion despite having anodes, it might indicate that the anodes need replacing or that there’s an issue with the electrical grounding.

- Winter Storage: If you’re storing your boat for the winter, make sure to check the anodes before and after the storage period. Saltwater can be particularly harsh, and winter storage might lead to unexpected corrosion if the anodes are not in good condition.

Common Mistakes to Avoid

Here are a few common pitfalls to avoid when dealing with zinc anodes:

- Using the Wrong Type: Ensure you’re using zinc anodes for saltwater and not aluminum or magnesium anodes meant for other environments.

- Ignoring Corrosion: Don’t ignore signs of corrosion on your engine parts. If the anodes are worn out or missing, the engine components are at risk.

- Improper Installation: Always follow the manufacturer’s instructions for installation. An incorrectly installed anode can be ineffective or even cause damage.

- Neglecting Regular Maintenance: Regular inspection and maintenance are key to ensuring the longevity of your zinc anodes and the protection of your engine.

Wrapping Up

In the world of marine engines, zinc anodes might not be the most glamorous component, but they are certainly one of the most vital. By understanding their role, choosing the right anode, and maintaining it properly, you can protect your engine from corrosion and ensure smooth sailing for years to come.

Feel free to share your experiences or ask any questions about zinc anodes in the comments below. Happy boating!