Owning a boat brings a mix of adventure and responsibility. Whether you’re leisurely cruising or fishing in remote waters, the performance of your boat’s systems—especially its engine and hydraulics—plays a crucial role in your experience. One small but vital component that often goes unnoticed until it fails is the marine solenoid valve. These unassuming devices regulate fluid flow, controlling everything from your boat’s fuel to hydraulic systems. Selecting the right marine solenoid valve for your boat is essential to ensure reliability and smooth operation. In this guide, I’ll walk you through everything you need to know about choosing the best solenoid valve for your marine application based on personal experience, a bit of history, and some handy tips.

What is a Marine Solenoid Valve?

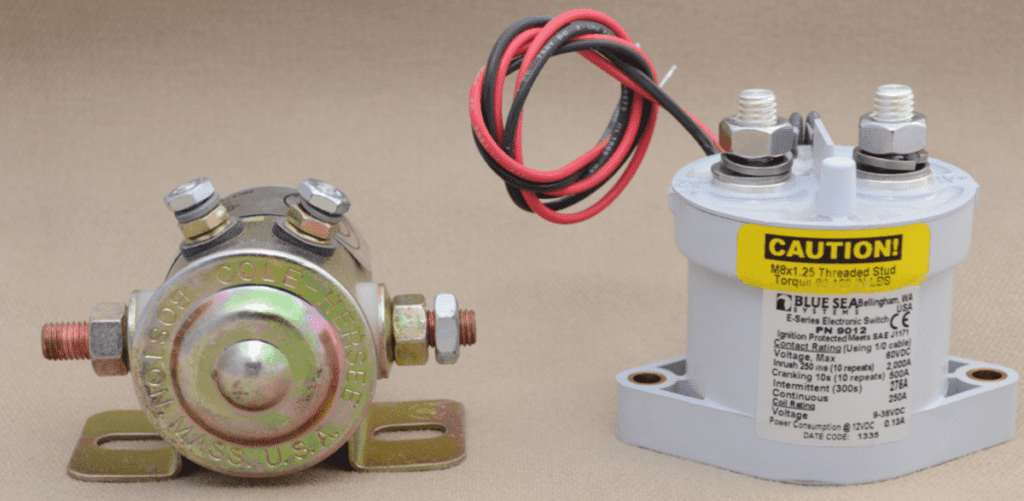

To start with the basics, a marine solenoid valve is an electromechanical device that controls the flow of liquid or gas within a system. When powered by an electric current, the solenoid (essentially a coil of wire) creates a magnetic field that triggers a plunger inside the valve to open or close. Depending on the system, this could be controlling fuel, hydraulic oil, or water flow. It’s widely used in marine engines, fuel systems, and even water management on boats.

In simpler terms, it’s the gatekeeper that allows fluids to move through your boat’s system based on your commands, whether you’re revving up the engine or adjusting the hydraulics. Without it, many core functions would grind to a halt.

A Brief History: Solenoid Valves in Marine Applications

Before solenoid valves became the go-to technology for controlling fluid flow on boats, manual valves and mechanical actuators were the standard. If you were boating in the early 20th century, you would have to manually turn knobs and levers to direct fuel or water to different parts of the vessel. While this worked, it was inefficient and often cumbersome—especially when trying to control multiple systems at once.

With the invention of electric solenoids in the 20th century, things changed dramatically. By the 1950s, solenoid valves started to make their way into marine applications, automating what used to be tedious tasks. This not only made boat operation more efficient but also safer, as solenoid valves reduced the likelihood of human error in critical situations, like fuel management during rough seas.

Types of Marine Solenoid Valves

Not all solenoid valves are created equal. Understanding the different types and their applications will help you make an informed decision when selecting the right one for your boat. Here are the most common types used in marine systems:

1. Direct Acting Solenoid Valve

This is the simplest type of solenoid valve. It works by directly opening or closing the valve as soon as the solenoid coil is energized or de-energized. They are often used in smaller applications where flow rate is low, such as in bilge pump systems or small fuel lines.

Pros:

- Simple design, fewer parts.

- Quick response time.

- Reliable in low-pressure systems.

Cons:

- Limited to low-flow and low-pressure applications.

2. Pilot-Operated Solenoid Valve

These valves use a small internal passage to create a pressure differential that helps open or close the valve. They’re commonly used in fuel systems and hydraulic applications on boats, where flow and pressure are higher.

Pros:

- Efficient for high-flow systems.

- Works well in high-pressure environments.

Cons:

- Slightly slower than direct-acting valves.

- More complex and may require more maintenance.

3. Two-Way Solenoid Valve

This type of valve has two ports, one for inlet and one for outlet. It’s used to start and stop the flow of fluids, making it perfect for simple on/off applications, like controlling the flow of fresh water or fuel on a boat.

Pros:

- Basic design.

- Suitable for on/off control of liquids or gases.

Cons:

- Not suitable for flow modulation.

4. Three-Way Solenoid Valve

A three-way valve has three ports, which allows it to alternate between two circuits. These are ideal for systems that require switching between two different fluid sources or directing flow in more than one direction.

Pros:

- Versatile, can handle multiple systems.

- Ideal for switching applications.

Cons:

- More complex and typically larger.

5. Four-Way Solenoid Valve

Commonly used in hydraulic systems, a four-way solenoid valve is designed to control the movement of double-acting cylinders. It has four or more ports to manage the flow of hydraulic fluids in both directions.

Pros:

- Perfect for controlling hydraulic actuators.

- Offers full control over fluid direction.

Cons:

- Complex, may require professional installation.

Factors to Consider When Choosing a Marine Solenoid Valve

Now that you have an understanding of the different types of solenoid valves, it’s time to get into the key factors you need to consider when choosing the right one for your boat. Here’s a quick checklist of things to keep in mind:

1. Material and Corrosion Resistance

Marine environments are harsh, with saltwater and humidity being major culprits for corrosion. Therefore, you’ll want to select a valve made from corrosion-resistant materials such as marine-grade stainless steel, bronze, or plastic for freshwater systems. Brass valves are also a popular choice, but be cautious—over time, they can succumb to the corrosive effects of seawater.

2. Voltage Requirements

Most marine solenoid valves run on either 12V or 24V DC power. Ensure that the voltage of the solenoid valve matches your boat’s electrical system. Using the wrong voltage could cause inefficient operation or even damage to your boat’s electrical system.

3. Pressure and Flow Rate

Make sure the valve you choose can handle the pressure and flow rate of your system. For example, if you’re using the valve in a fuel system, the flow rate and pressure needs may be higher than those for a bilge pump system.

4. Application

Is the valve controlling fuel, water, or hydraulic fluid? Each type of fluid has specific requirements in terms of material and flow characteristics. A valve designed for water may not function properly in a fuel system, and vice versa.

5. Sealing and Leakage Protection

A marine solenoid valve should have excellent sealing capabilities to prevent leaks, which can be dangerous, especially in fuel systems. Look for valves with high-quality seals that can withstand high pressure and fluctuating temperatures.

6. Manual Override

Some solenoid valves come with a manual override feature, which allows you to open or close the valve manually in case of an electrical failure. This can be a lifesaver in emergency situations.

Maintenance Tips for Marine Solenoid Valves

Regular maintenance is essential to keep your solenoid valves working smoothly and extend their lifespan. Based on personal experience, here’s a simple DIY guide to keeping your marine solenoid valve in top shape:

1. Regular Inspections

Check the valve for signs of corrosion, wear, or leaks at least once a season. If you use your boat frequently, consider inspecting it more often.

2. Clean the Valve

Salt deposits and dirt can build up on the valve over time, affecting its performance. To clean, remove the valve, rinse it in freshwater, and use a soft brush to scrub away any debris. Make sure the electrical components stay dry.

3. Test the Functionality

Before heading out for the season, test your solenoid valves to ensure they’re functioning correctly. You can do this by powering them on and checking the flow in the connected systems.

4. Lubrication

While solenoid valves don’t need much lubrication, applying a small amount of marine-grade grease to the seals and moving parts can help prolong the valve’s life, especially in high-use systems.

Final Thoughts: Why the Right Marine Solenoid Valve Matters

Selecting the right solenoid valve for your boat may seem like a small decision, but its impact on your vessel’s performance is anything but minor. Whether you’re cruising around your local marina or tackling a long offshore trip, the reliability of your boat’s fluid systems can make all the difference. After all, nothing ruins a great day on the water faster than a failed fuel valve or leaky hydraulic system.

By understanding the different types of solenoid valves, their functions, and the key factors to consider, you can ensure that your boat remains in peak operating condition. Take the time to choose wisely, maintain regularly, and enjoy the peace of mind that comes with knowing your boat’s systems are in good hands.

If you’re in the market for reliable marine solenoid valves, be sure to check out the range available at eParts. We’ve got you covered for all your marine valve needs.